Manufacturing

GABION BOX-Machine Made from Heavy Coated GI Wire.

Sector & Application

Application of GABION BOX

Scope of application of Gabion boxes covers the furnishing of materials and construction of gabion works that may be required to act as buttresses, retaining walls, catch wall, stream or river training structures, check dams within gullies, or placed as mattresses, to prevent stream or gully erosion and aesthetic fence structure for garden etc.

Agribusiness

Agriculture and the agribusiness market sector experience many similar problems to the civil and environmental markets, although often on a smaller scale.

Preventing Slope erosion

Protection of soil erosion an effective and reliable channeling works are needed for irrigation or land drainage purposes.

The protection of the environment area involves protecting weak soils, reducing erosion through stabilization and value for money.

Coastal & River Control Works

Soil-bioengineering techniques and the use of natural materials and plants to provide erosion protection for coastal waterways, river works etc.

Landscape & Architecture

Gabions use as architectural with landscape a well-constructed gabion wall can provide an intimate and reflective area offering sound proofing, privacy and beauty. Gabions can be used as landscaping walls, retaining etc. Rock filled gabion units are also used for a natural looking aesthetic statement.

The protection of the environment area involves protecting weak soils, reducing erosion through stabilization and value for money.

Retaining Walls & Soil Reinforcement

Retaining walls and soil reinforcement structures to suit different site conditions, performance and aesthetic requirements and it could be a small retaining walls to a massive reinforced soil structure on a major highway.

Fencing

Fencing for use in security, control and protection to provide quality, strength and value-for-money. Fencing durability is provided as the wire is protected with heavy duty galvanizing coating.

Products

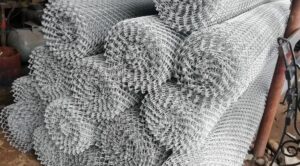

Production plant of GABION BOX is situated at Gagangauda, Pokhara where different sizes and designs of GABION BOXES are being manufactured by machine of latest technology using high quality heavily zinc coated GI wires.

Production plant of GABION BOX is situated at Gagangauda, Pokhara where different sizes and designs of GABION BOXES are being manufactured by machine of latest technology using high quality heavily zinc coated GI wires.

Standard Size of GI Wire and Specification of Mechanically Woven GABION BOX

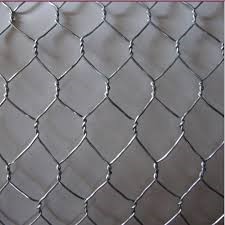

The mild steel wire complying with NS 163-2045 and zinc. Gabions are manufactured in the standard sizes with mesh and wire sizes as shown in Table 24.3, Table 24.4 and 24.6. This specification covers mechanically woven, mechanically selvedge gabions and Reno mattresses produced from double twist wire mesh used for manufacturing, assembling and installation of the product. Gabions boxes made of hexagonal double twisted woven wire mesh, divided into cells by means of diaphragms which help to reinforce and strengthen the structures. They are interconnected with other similar units and filled with stones at the project site to form flexible, permeable and monolithic structures such as gravity retaining walls, channel linings, dams etc.

Table No 24.3 Mesh Type and Size

| Mesh Type | ‘D’ Nominal Size. mm | Tolerances |

| 10×12 | 100 | +16% to – 4% |

| 8×10 | 80 | |

| 6×8 | 60 |

Table No. 24.4 (A) Mesh & box characteristics for Gabions

| Mesh Type | 10×12 | ||||||

| ‘D’ Type | 100 | ||||||

| Wire Type | Zn Coated | Zn-Al alloy Coated | Zn + PVC Coated | Zn-Al alloy + PA6 Coated | |||

| Mesh Wire Dia., mm | 2.70 | 300 | 2.70 | 3.00 | 2.70/3.70֗֗ | 2.70/3.70֗֗ | |

|

Edge /Selvedge Wire Dia., mm |

3.40 | 3.90 | 3.40 | 3.90 | 3.40/4.40֗֗ | 3.40/4.40֗֗ | |

| Lacing wire Dia, mm | 2.20 | 2.40 | 2.20 | 2.40 | 2.20/3.20 | 2.20/3.20 | |

| PVC /PA6 coating thickness, mm |

N. A |

N. A |

Nominal-0.50 Minimum – 0.38 | Nominal-0.50 Minimum – 0.38 | |||

|

Typical Sizes

Length x Width x Height (m) / Number of diaphragms |

Box Gabion: 4 x 1 x 1 / 3 Nos, 3 x 1 x 1 / 12 Nos, 2 x 1 x 1 / 1 No, 1.5 x 1x 1 / 0 No, 2 x 1 x 0.5 / 1 No, 3 x 1 x 0.5 / 2 Nos, 4 x 1 x 0.5 / 3 Nos, Jumbo Gabions: 5 x 1.5 x 1 / 4 Nos, 4 x 1.5 x 1 /3 Nos, 3 x 1.5 x 1 / 2 No, 5 x 2 x1 / 4 Nos, 4 x 2 x 1 / 3 Nos, 3 x 2 x 1 / 2 No, 5 x 1.5 x 0.5 / 4 Nos, 4 x 1.5 x 0.5 / Nos, 3 x 1.5 x 0.5 / 2 No, 5 x 2 x 0.5 / 4 Nos, 4 x 2 x 0.5 / 3 Nos, 3 x 2 x 0.5 / 2 No |

||||||

|

Tolerance in Size of Gabion Boxes |

Length & Width. ± 5%; Height ± 5% | ||||||

Physical Properties

| Table 24.6 Minimum Mass of Zinc Coating and Permitted tolerance on galvanized steel wire diameters | ||

|

Nominal Diameter of Galvanized wire, mm |

Mass of Zinc coating, g/m² | Permitted tolerances (+/-) wire diameter, mm |

| 2.00 | 240 | 0.05 |

| 2.20 | 240 | 0.06 |

| 2.40 | 260 | 0.06 |

| 2.70 | 260 | 0.07 |

| 3.00 | 270 | 0.08 |

| 3.40 | 270 | 0.09 |

| 3.90 | 280 | 0.10 |

Benefits of gabion walls

- Aesthetic – gabion walls look natural and by using

natural materials fits into the environment

natural materials fits into the environment

• Compatibility with the environment – using the material made by excavations the costs of acquisition and transport are significantly reduced

• Water permeability – gabion walls are permeable and are not damaged by passing water

• Efficiency of gabion walls can increase in time, since the vegetation fills voids and strengthens the wall structure

• Soil movements don’t negatively influence gabion walls, which is an advantage in regard to stiffer structures (reinforced concrete walls)

• Longevity – stone blocks are materials that are frequently used because of their longevity, durability and stability. Usually, the stone is selected because of aesthetic attributes or the possibility of excavation produced material usage.

Gabion baskets are folded when transported to the construction site in order to take up as little as space as possible. After transport, baskets are unfolded, connected and prepared for positioning.

Our Products